The BK Groups Epic Coating Academy is South India's leading Industrial Spray Gun Accessories and Equipment distributor. They provide various types of feed in Manual Spray gun models such as pressure (X-202-12P), suction (X-202-13S, (X-202-14S), (X-202-15S), (X-202-18S), (X-202-20S), (X-202-25S), gravity (X-202-13G), (X-202-14G), (X-202-15G), (X-202-20G), (X-202-25G).

Some of the Automatic spray gun models and their feed are Pressure (XA-11-08P), (XA-11-10P), (XA-11-13P), (XA-11-15P), (XA-11-20P), (XA-11-25P). These are some of the models in both automatic and manual. We also provide more varieties in each model with different kinds of air caps, accurate air pressure, and various pattern width and weight sizes.

Spray Painting

Blasting solutions

Spray Guns Accessories

Coating Application Training

Automotive Spray Services

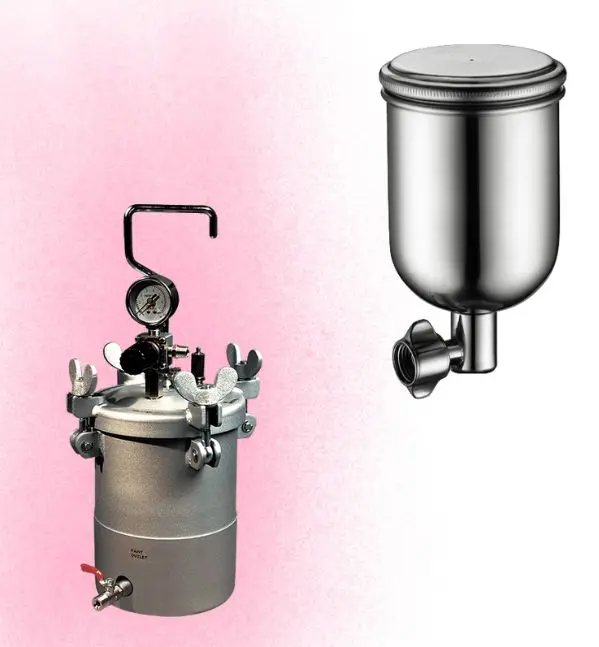

Epic coating academy provides a wide variety of spray gun accessories, including Automated and Manual, India's leading spray painting equipment and accessories. The HVLP, gravity feed, suction feed, pressure feed, and electrostatic paint spray equipment. A suitable agitator, pressure pot, paint pumps of various capacities, and other equipment.

The choice of painting equipment is essential for efficiency gains excellent advice on using crucial spray equipment to reduce paint waste by at least 15%. To suit the demands of our customers and increase efficiency and quality, we import imperative tools and machines for coating and painting from Japan and Taiwan. Automatic Spray Guns used for painting, coating, and switching to a spray gun can eliminate the unevenness and improve yields if the conventional method results in an uneven layer. In these cases, an automatic spray gun can reduce the fluid and apply an appropriate amount.

Our Epic Coting Academy provides HVLP spray guns in India that function at low pressure and utilizes a large quantity of air. The advantage of spray painting and low-pressure spraying is enhanced paint transfer on the substrate. A spray gun has development information and an air channel (the compressed air pipe). The spray nozzles spray and atomize a variety of air and paint. Old HPLV guns, on the other hand, run at high pressure, causing a considerable portion of the paint to rebound off the substrate, resulting in a sub-optimal product transfer rate and product loss. In comparison to old standard spray guns, they require a larger compressor. HVLP Spray gun's pressure and flow are necessary to complete the painting process effectively and provide an excellent metalized or gloss finish.

The different areas of industry focus on coating solutions. These are the simple secret to coating with Epic coating services.

The BK Groups, Epic Coating academy offers pressure-feed spray guns in India that can spray paint constantly and methodically to high-speed spray guns with a high paint transmission efficiency. The spray cannon includes an air-adjustable lever. The spray gun is light in weight, with a stainless steel fluid route. Pressure feed spray guns, in particular, employ a pressure tank with two regulators. With a dual-regulated pressure tank, you may have specific control over the fluid pressure given to the material and the air that atomizes it.

Another advantage of pressure sprayers over gravity and suction sprayers is the capacity to spray larger materials, which may struggle to transfer material via the gun due to the thickness of the substance. Pot life refers to the time that multiple component coatings or paints may be applied to a surface. It starts when the mixing is finished and stops when it is no longer acceptable for application or has been set because a spray cannon and a pressure tank are generally required rather than a suction spray gun or gravity.

The electrostatic painting process includes more charging paint particles to paint a work item. The atomized particles in electrostatic spray painting are electrically charged to reject one another and spread out uniformly when they leave the spray nozzle. It is grounded, or the painted object receives a negative charge. When atomized paint is given a significant electric charge, a large amount of paint is applied to the component.

After that, the paint is pulled to the item, resulting in an equal application to wet spray painting and a large increase in the amount of paint that sticks to the object. Turbocharging, post-atomization, and direct charging are the three most prevalent ways to charge liquids or powders. Another advantage of this approach is that it allows you to paint over difficult-to-reach areas.

The entire container is baked to ensure proper adhesion to the paint, and the powder turns into a plastic-like material. Electrostatic painting can enhance processes such as solvent and water-based paints, as well as automotive and aerospace. Electrostatics can increase productivity, reduce paint overspray, and allow you to use less paint.

In South India, Epic Coating Academy, a division of The BK Groups solutions, is an Authorized Distributor of Ranox. It began manufacturing spray guns in Taiwan in 1985 and expanded the business by introducing pressure tanks in 1994. Our Epic Coating Academy provides the best quality, both automatic and manual Sprayers, which are widely available.

Epic Coating Academy's BK groups' spray guns feature exceptional atomization and conform patterns. The nozzles and needles are made of high-quality stainless steel. We collaborate with Taiwanese and Japanese paint equipment manufacturers. We serve as great service providers as well as authorized distributors.

We get metalizing, and coating application services from Epic services, which are too good, and their work is precise. We are pleased to acquire their service, especially coating service, where the quality of work is highly satisfying. They have suitable coating applications and well-trained painters. The best thing is they maintain professionalism in their work.

We were searching for many to get a suitable consultants and we graciously got EPIC coating academy. They are very skillful, in each and everything the experts gave potential solutions for our new paint booth and organized systematic approaches. Their planning is very helpful and gives a boost to the team. We are grateful to the EPIC team.